Road studs are small raised markers typically installed on road surfaces. Their primary function is to provide visual guidance and warnings to drivers, especially in low-light conditions or adverse weather, helping drivers better assess road conditions. Compared to traditional road markings, road studs have a raised physical form. They not only convey information visually but also, in some special types, provide tactile feedback to drivers through vibrations generated by vehicle rolling, further enhancing the warning effect.

The development of road studs has been a long process. Early road studs were primarily made from natural materials such as stone and wood, with simple structures mainly used to mark road boundaries. With the advancement of industrial technology, metal road studs began to emerge, significantly improving durability. In modern times, with the progress of polymer materials and optical technology, road studs have made significant strides in material quality and reflective performance, becoming more versatile in function. They have evolved from single-purpose marking devices into comprehensive traffic facilities that combine guidance, warning, and other functions.

Road studs come in a variety of types, each with unique characteristics in terms of material, size, and performance to suit different application scenarios.

Glass road studs (e.g., UK-G001): Dimensions are φ100×50 mm, made of tempered glass. This material is not only robust and durable, capable of withstanding prolonged vehicle rolling without damage, but also has excellent reflective performance, clearly visible under light exposure, and maintains good reflective effects even in heavy rain.

Reflective road studs (e.g., UK-R001): Dimensions are 100×100×18mm, made from ABS+PMMA material. ABS material offers good impact resistance and wear resistance, while PMMA ensures excellent reflective performance, effectively enhancing visibility on the road, allowing drivers to detect them from a distance.

Aluminium-bodied glass bead road studs (e.g., UK-B001): Dimensions are 100×100×20+75 mm, combining the durability of an aluminium shell with the reflective properties of glass beads. The aluminium shell can withstand heavy vehicle rolling, while the glass beads efficiently reflect light, achieving a good balance between durability and reflective performance, making them suitable for use on major roads with high traffic volume.

Other types: For example, the UK-R005 uses an acrylic shell + PMMA reflective sheet, with dimensions of 100×100×18 mm. The acrylic shell has excellent weather resistance and is not easily affected by UV rays, preventing aging; the UK-C001 is made of ceramic material, available in yellow and white, with ceramic material being heat-resistant and corrosion-resistant, suitable for use on roads in special industrial areas. These road studs, with their unique materials and dimensions, can adapt to various road environments.

In low-light environments such as at night, as well as during adverse weather conditions like rain, fog, or snow, drivers’ visibility is significantly impaired. Traditional road markings often become blurred in such conditions, while road studs reflect vehicle headlights, creating bright light points or bands. Especially in foggy weather, the reflective properties of road studs can penetrate the fog, making road boundaries, lane separations, and potential hazard zones more clearly visible to drivers, helping them accurately judge road direction and avoid accidents caused by poor visibility.

Road studs clearly mark key areas such as lanes, curves, intersections, and pedestrian crossings, guiding drivers to stay in the correct lane. At curves, continuously arranged road studs alert drivers to slow down and turn in advance; at intersections, road studs clearly indicate the direction of travel for lanes, reducing lane-cutting incidents. Additionally, the raised design of road studs causes drivers to feel vibrations when the vehicle deviates from the lane, prompting them to correct their direction promptly, thereby reducing the risk of lane deviation and collisions, and effectively lowering the incidence of traffic accidents.

Road studs of different materials and sizes can be applied to various road surfaces, including urban roads, highways, and mountain roads. Urban roads have high and complex traffic volumes, so using wear-resistant, highly reflective road studs ensures long-term effectiveness; highways have high speeds, so road studs need stronger reflective penetration and compression resistance; mountain roads have many curves and slopes, and road studs can provide continuous guidance to drivers, helping them drive safely. For example, aluminum road studs have stronger compression resistance and are suitable for roads with heavy traffic, meeting the needs of different road conditions.

Road studs complement traditional road signs and markings. Road signs are typically placed alongside or above the road, providing overall guidance information such as speed limits and directional indicators, while road studs are installed on the road surface, providing continuous and close-range visual cues. When drivers are far from road signs, road studs can preemptively convey relevant information. As drivers approach road signs, road studs can complement the signs, ensuring drivers always have access to effective road condition information during travel, thereby avoiding violations or hazards caused by missing sign information.

Installing road studs on lane dividers, road edges, and near intersections in urban roads helps maintain traffic order. During peak hours with heavy traffic, the clear reflectivity of road studs allows drivers to quickly identify lanes, reducing arbitrary lane changes. At intersections, road studs mark stop lines, turning lanes, etc., guiding vehicles to travel orderly and improving intersection efficiency.

Using road studs on long straight sections, curves, and slopes of motorways can alert drivers to lane changes and help control speed. On long straight sections, drivers are prone to fatigue, and the reflective properties of road studs create a visual focal point, reducing driver fatigue; on curves, road studs are arranged along the curve’s trajectory to guide drivers to turn correctly; on slopes, road studs allow drivers to anticipate changes in gradient and adjust speed in advance, which is particularly important for nighttime long-distance driving.

In special sections such as school zones, construction zones, and pedestrian crossings, road studs can highlight the location of these areas. Road studs in school zones are typically coloured in a conspicuous colour, such as yellow, to remind drivers to slow down and yield to students; road studs in construction zones mark the construction area and detour routes, guiding vehicles to pass safely; road studs at pedestrian crossings allow drivers to detect the area where pedestrians are crossing the road from a distance, enabling them to slow down in advance and ensure pedestrian safety.

When selecting road studs, factors such as traffic volume, vehicle speed, and climatic conditions must be considered. Roads with high traffic volume and high vehicle speeds should use road studs with strong load-bearing capacity and excellent reflective performance, such as aluminium-bodied glass bead road studs; in regions with frequent rain or fog, road studs with strong reflective penetration should be prioritised; for special environments like chemical industrial parks, corrosion-resistant road studs must be selected.

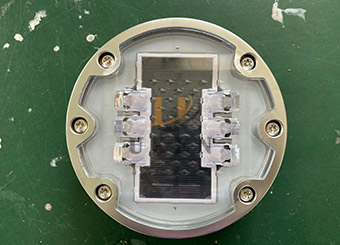

To ensure the proper functioning of road studs, regular maintenance and care are necessary. Dust and debris on the surface of the road studs should be promptly removed to avoid affecting their reflective performance. Inspect the road studs for loosening or damage, and promptly repair or replace them if issues are found. For solar-powered road studs, regularly check the battery charge level and cleanliness of the solar panels to ensure they can store energy and emit light normally.

Road studs are indispensable traffic safety facilities. From early simple marking tools to today’s multifunctional comprehensive traffic guidance devices, the development of road studs reflects the traffic industry’s relentless pursuit of safety. With their diverse types and excellent functions, they play a crucial role in enhancing road visibility, improving traffic safety, and adapting to various road environments. Selecting appropriate road studs based on specific road conditions and conducting proper maintenance and upkeep are of great significance for ensuring smooth and safe traffic flow. With the continuous advancement of technology, road studs will play an even more important role in the field of traffic safety.