A guardrail contour marker is a safety device installed on road guardrails, typically made of high-visibility materials such as plastic or metal with reflective strips. Its primary function is to clearly outline the shape and position of the guardrail, enabling drivers to accurately identify road boundaries under various conditions.

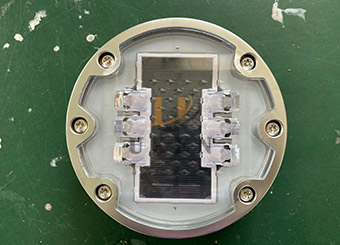

Fixed Base: Securely connected to the guardrail to ensure the marker remains in place under external forces such as vehicle impacts, wind, and rain.

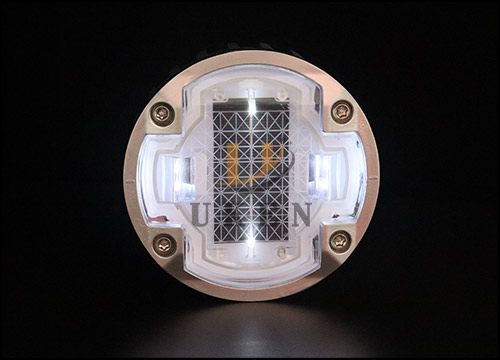

Main Body: Equipped with reflective elements (e.g., reflective film, glass beads), which are the core components for achieving visibility.

Protective Layer: Covering the surface of the main body, it provides weather resistance and impact resistance, extending the service life of the marker.

During periods of low light (night, dawn, dusk) and adverse weather conditions (rain, fog, snow), the colour and contours of guardrails can become blurred. Contour markers use reflective or high-brightness designs to make the presence and direction of guardrails clearly visible, helping drivers anticipate road edges in advance.

Continuously arranged contour markers form visual guide lines along road curves, slopes, and lane-changing areas. For example, at bends, the arrangement trajectory of contour markers directly indicates the turning angle to drivers; on slopes, they reinforce the perception of road undulations, prompting drivers to adjust speed and direction in a timely manner.

On one hand, contour markers remind drivers to maintain a safe distance from guardrails, reducing collisions caused by distraction or operational errors; on the other hand, even if a collision occurs, some contour markers can use their reflective properties to alert subsequent vehicles to the accident site in advance, reducing the likelihood of secondary accidents.

At night, with dim lighting, guardrails are difficult to observe directly. At this time, the reflective material of contour markers reflects the light from vehicle headlights, forming a continuous ‘light band.’ This light band clearly displays the direction of the guardrail, preventing drivers from veering off the lane or colliding with the guardrail due to misjudgment.

In rainy or foggy weather, visibility is significantly reduced, limiting the effectiveness of traditional road markings. The high-contrast colours (such as yellow or orange) and strong reflective properties of contour markers can penetrate rain and fog, allowing drivers to identify the location of guardrails from a distance and avoid losing control of the vehicle and veering off the road.

Mountainous roads: With numerous sharp bends and steep slopes, contour markers can highlight the curvature and height changes of guardrails, helping drivers adapt to complex terrain.

Overpasses and tunnels: Tunnels have limited lighting, and overpasses have no obstructions on either side. Contour markers can reinforce the sense of road boundaries, reducing drivers’ spatial judgement errors.

Using high-quality reflective film or glass bead technology, contour markers can efficiently reflect light even in low-light conditions. This feature ensures that contour markers are clearly visible to drivers at night, in tunnels, and other environments.

UV resistance: Maintains colour and performance stability even after prolonged exposure to sunlight.

Temperature and corrosion resistance: Withstands extreme climates such as high temperatures, extreme cold, and rain/snow, while resisting road oil and dust corrosion.

Easy Installation: Can be securely fixed to various types of guardrails (such as corrugated guardrails and concrete guardrails) using simple methods like clips or screws, without requiring complex construction.

Simple Maintenance: The surface does not easily accumulate dust, making daily cleaning convenient; if damage occurs, replacing individual units is cost-effective and does not affect the overall guidance effect.

Road Grade: Highways with heavy traffic and high speeds require contour markers with high reflectivity and impact resistance; urban roads can opt for products with moderate performance based on traffic volume.

Climate Characteristics: In regions with heavy rain and fog, prioritise models with excellent waterproofing and strong reflective penetration; in high-temperature or extremely cold regions, focus on material temperature resistance.

Regular Cleaning: Wipe the surface with clean water or a neutral detergent to prevent dust or grease from covering the surface and affecting the reflective effect.

Regular Inspection: Check for loosening, damage, or peeling of the reflective layer. Replace any damaged markers promptly to ensure continuous and effective operation.

They provide an intuitive visual reference, reducing the difficulty of judging road boundaries, especially in complex environments, thereby alleviating driving fatigue and enhancing driving safety.

By reducing the incidence of guardrail-related accidents, they decrease the costs associated with accident handling and guardrail repairs; simultaneously, they enhance the overall safety level of the road network, ensuring smooth traffic flow.

Though small in size, guardrail contour markers are an indispensable component of the road safety system. By enhancing visibility, guiding direction, and reducing risks, they safeguard the safety of vehicles and personnel in various environments. Proper selection and regular maintenance ensure that this ‘guardian of road boundaries’ continues to play its role, contributing to road traffic safety.