Intersections are critical nodes in the road traffic system and high-risk areas for traffic accidents. Vehicles converge, turn, and change lanes here, while pedestrians frequently cross, resulting in complex and diverse behaviour patterns among traffic participants. According to statistics from traffic authorities, approximately 40% of traffic accidents occur at intersections in urban roads, and this proportion rises to as high as 60% in rural roads. One of the primary causes of accidents is the ambiguity of traffic signs and insufficient guidance facilities at intersections, which prevent drivers and pedestrians from obtaining accurate road information in a timely manner.

Among various facilities designed to enhance intersection traffic safety, aluminium road studs stand out due to their unique performance advantages, making them an effective choice for improving intersection traffic conditions. This seemingly small traffic facility, by reinforcing road markings and guiding vehicle direction, can significantly reduce the incidence of accidents at intersections.

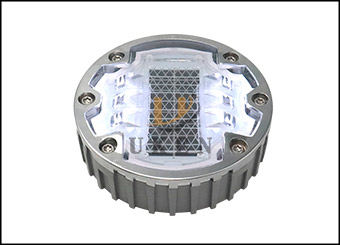

Aluminium road studs are made of high-strength aluminium alloy, combining both lightweight and high-strength properties. Compared to steel road studs, aluminium road studs are approximately 40% lighter, making the installation process more convenient and effectively reducing construction difficulty and labour costs. Additionally, aluminium alloy exhibits excellent corrosion resistance, remaining unaffected by rust or damage in humid, acidic, or alkaline environments such as coastal areas with high salt fog or industrial pollution zones. Its service life can extend up to 5–8 years.

The reflective performance of aluminium road studs is one of their core advantages. By embedding high-performance reflective sheets or applying reflective coatings, they produce a strong reflective effect when illuminated by vehicle headlights. Even under adverse weather conditions such as nighttime, fog, rain, or dust storms, their reflective distance can exceed 300 metres, enabling drivers to clearly identify road intersections, lane boundaries, and hazardous areas from a distance and make driving decisions in advance.

In daily use, aluminium road studs demonstrate excellent wear resistance and impact resistance. Their robust structure can withstand repeated碾压 by heavy vehicles without deformation or cracking. Compared to plastic road studs, aluminium road studs are more wear-resistant; compared to steel road studs, their lower maintenance costs and moderate prices make them more cost-effective in the long term. According to calculations, the annual maintenance cost at intersections using aluminium road studs can be reduced by 30% compared to those using steel road studs.

At intersections, aluminium road studs, through scientific layout, serve as the ‘invisible traffic directors.’ At lane dividing lines, continuously arranged spikes guide vehicles to maintain the correct driving trajectory and prevent arbitrary lane changes; in turning lanes, spikes clearly indicate the turning path, reducing collisions caused by improper turning angles. For example, at intersections with traffic islands, aluminium spikes arranged along the edge of the traffic island effectively guide vehicles to bypass orderly, improving intersection traffic efficiency.

Aluminium road studs complement traffic markings and traffic lights to form a clear intersection signage system. Even when traffic markings become worn from prolonged use, aluminium road studs continue to provide distinct signage. At night or in low-light conditions, their reflective properties compensate for the reduced visibility of markings, enabling drivers and pedestrians to accurately determine intersection boundaries, stop line locations, and lane directions, ensuring orderly traffic flow.

In hazardous areas at intersections, aluminium road studs play a crucial warning role. Before pedestrian crossings, the reflective properties of road studs remind drivers to slow down in advance and yield to pedestrians. At the edges of traffic islands or near obstacles, road studs use high-brightness reflection to warn drivers of potential hazards, preventing scrapes or collisions. These warning functions effectively enhance the safety awareness of traffic participants at intersections.

The installation location of aluminium road studs directly affects their effectiveness. At intersections, they should be prioritised for installation at critical locations such as lane dividing lines, stop lines, traffic flow lines, and pedestrian crossing lines. Before installation, the ground must be cleaned and ground to ensure the installation surface is flat and dry. There are two main fixing methods: adhesive bonding and screw fixation. Adhesive bonding is suitable for smooth surfaces like asphalt and concrete, using high-strength road-specific adhesive to ensure the studs are securely bonded to the ground; screw fixation is more suitable for areas with unstable foundations or where frequent disassembly and maintenance are required. During installation, the spacing between road studs (typically 15–20 metres) and height (flush with the road surface or slightly elevated by 1–2 millimetres) must be strictly controlled to ensure optimal reflective performance and driving comfort.

Routine maintenance of aluminium road studs is relatively simple. Regularly clean dust, dirt, oil stains, and other debris from the surface of the road studs using a soft cloth or brush to maintain their reflective performance. Inspect the stability of the road studs monthly, and reinforce any loose studs promptly. Immediately replace any road studs damaged by vehicle collisions or other causes. Through simple routine maintenance, aluminium road studs can continue to function effectively.

At a busy intersection in the city centre of a certain city, there were previously 5–6 traffic accidents per month due to unclear lane markings and severe vehicle congestion. After the renovation using aluminium track spikes, reflective aluminium track spikes were installed along the lane boundaries, turning lanes, and the edges of traffic islands, complemented by newly repainted traffic markings. Within six months of the renovation, the accident rate at the intersection decreased by 70%, and vehicle通行 efficiency improved by approximately 35%. Drivers reported that even at night or in rainy weather, they could clearly distinguish lanes and driving directions, significantly enhancing driving safety.

At a T-junction in a rural area, frequent traffic accidents occurred at night due to the absence of lighting facilities and clear traffic markings. After installing aluminium road studs, reflective studs were placed at the stop lines, pedestrian crossings, and curves of the intersection. These studs automatically reflect vehicle headlights at night, providing clear road guidance for passing vehicles and pedestrians. One year after the renovation, the nighttime accident rate at the intersection dropped from an annual average of 12 incidents to 2 incidents. Local residents reported feeling safer when travelling at night, and the traffic order at the intersection has also improved significantly.

Although plastic road studs are cheaper, they are far inferior to aluminium road studs in terms of strength and durability. Plastic road studs have weak impact resistance and are prone to damage under heavy vehicle碾压; their reflective coating also easily peels off, leading to a rapid decline in reflective performance. In contrast, aluminium road studs, with their high-strength material and high-quality reflective film, can maintain excellent performance in complex traffic environments and are more suitable for high-traffic scenarios like intersections.

While steel road studs are highly durable, they are heavy, making installation more difficult and costly. Additionally, steel road studs are prone to rust, requiring frequent maintenance and incurring high costs in humid environments. Aluminium road studs, on the other hand, are lightweight, corrosion-resistant, easy to install, and have lower overall costs over their lifecycle, demonstrating higher cost-effectiveness and suitability for intersection applications.

Aluminium road studs play an irreplaceable role in intersection traffic management due to their lightweight, high strength, excellent reflectivity, durability, and cost-effectiveness. By guiding traffic flow, reinforcing intersection signage, and providing effective warnings, they significantly enhance traffic safety and efficiency at intersections, creating a safer and more orderly travel environment for road users.

Whether it is the upgrading and renovation of urban roads or the improvement of rural traffic facilities, aluminium road studs are a high-quality option worthy of priority consideration. If you are planning an intersection traffic improvement project, please contact us for professional product consultation and solutions.